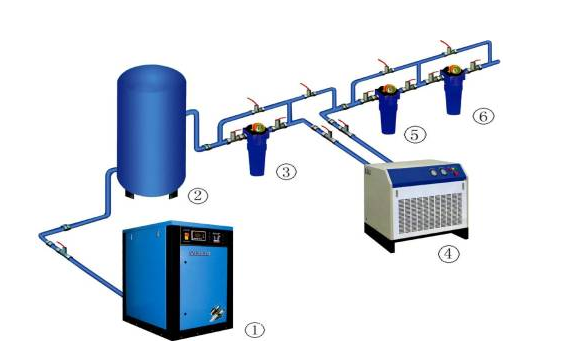

"Rëndësia e pajisjeve pas përpunimit të kompresorit të ajrit" Arsyeja pse unë shkrova këtë artikull është sepse nëse keni drejtuar një fabrikë, drejtoni një biznes ose keni përdorur një kompresor ajri, ju patjetër do të dini pse është e rëndësishme të instaloni pajisje pas përpunimit të kompresorit ajror. E thënë thjesht, është për të hequr papastërtitë dhe lagështinë në ajrin e ngjeshur. Në fakt, ashtu si sistemi hidraulik ka kërkesa të larta për pastërtinë e vajit hidraulik, sistemi pneumatik gjithashtu ka kërkesa të larta për ajrin e kompresuar.

Në shumë raste, ajri i kompresuar i shkarkuar nga kompresori i ajrit nuk mund të përdoret drejtpërdrejt nga pajisjet pneumatike. Për shkak se kompresori thith ajrin që përmban lagështi dhe pluhur nga atmosfera, temperatura e ajrit të kompresuar rritet në mbi 100 ° C. Në këtë kohë, një pjesë e vajit lubrifikues në kompresorin e ajrit gjithashtu bëhet i gaztë. Në këtë mënyrë, ajri i kompresuar i shkarkuar është gazi me temperaturë të lartë që përmban vaj, lagështi dhe pluhur. Nëse ky lloj ajri i kompresuar dërgohet drejtpërdrejt në sistemin pneumatik, për shkak të cilësisë së dobët të ajrit, besueshmëria dhe jeta e shërbimit të sistemit pneumatik do të zvogëlohet shumë (veçanërisht jeta e pajisjeve me përbërës nënshkrimi siç janë valvulat solenoid dhe cilindrat do të kenë një ndikim të madh). Humbjet që rezultojnë shpesh tejkalojnë shumë koston dhe kostot e mirëmbajtjes së pajisjes së trajtimit të burimit të ajrit, kështu që zgjedhja e saktë e sistemit të përpunimit të kompresorit të ajrit është absolutisht i nevojshëm.

Koha e postimit: MAR-01-2025